Hubs, a prominent online manufacturing platform, has recently unveiled its latest 3D Printing Trend Report. This comprehensive report draws from insights gathered from over a thousand customers and manufacturing partners, a thorough examination of news and media sources, and insights provided by leading market analyst firms.

The report sheds light on the growing adoption of 3D printing for large-scale orders, signifying its transformation from a niche hobbyist’s tool to a powerful industrial solution.

The survey, conducted in February 2023 and featuring 1,035 participants, provides a glimpse into the industry’s remarkable expansion. A substantial 71 percent of respondents revealed that they produced more 3D-printed parts in 2022 compared to the previous year.

This surge in 3D printing usage is vividly reflected in the industry’s market size, which reached an impressive $17.05 billion in 2022, boasting an annual growth rate of 13 percent. The primary driver behind this growth can be attributed to a staggering 83 percent of businesses reporting significant cost reductions achieved through 3D printing.

Hubs’ 3D Printing Trend Report cover image.

Hubs’ 3D Printing Trend Report cover image.

The upward trajectory in the 3D printing market is anticipated to persist into 2023. Drawing upon Hubs’ internal data and compounded annual growth rate (CAGR) projections from ten prominent market analysis firms, the 3D printing market is expected to expand by a remarkable 17 percent, ultimately reaching a substantial $19.9 billion by 2023. Notably, the polymer additive manufacturing (AM) sector generated more than double the revenue when compared to its metal counterpart. However, metal additive manufacturing experienced a more robust growth rate in 2022 and is poised to continue growing at an accelerated pace.

Turning our attention to printer hardware, there was a noteworthy surge in revenue in 2022, despite a 4 percent decrease in global shipments during the same period. This phenomenon is likely attributed to factors such as inflation and the escalating costs of manufacturing machines.

Among the different categories of 3D printers, personal 3D printers saw the most significant decrease in shipments, while industrial polymer systems experienced a marginal 2 percent decline. Contrarily, industrial metal systems witnessed a slight increase in shipments in 2022.

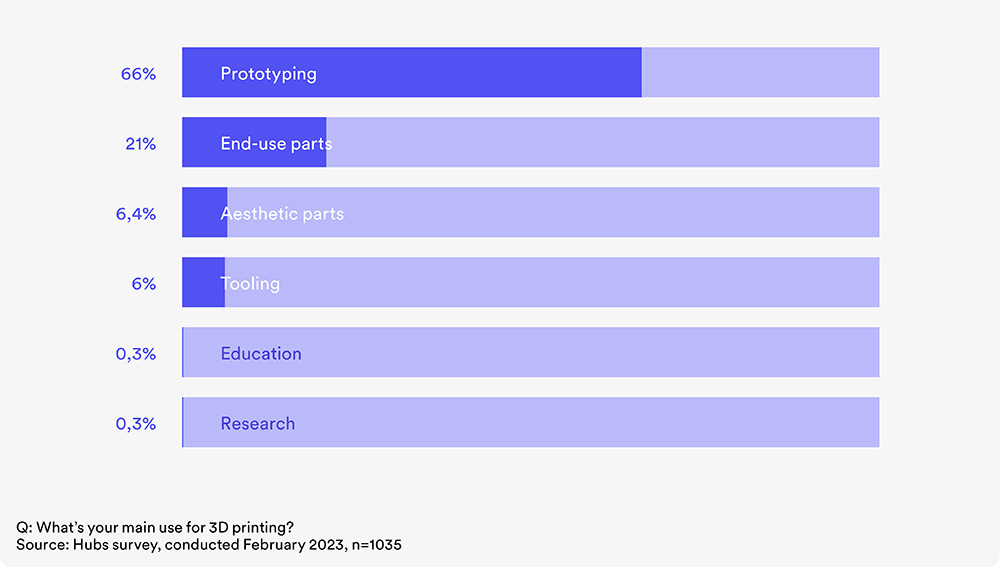

Top 3D printing applications.

Top 3D printing applications.

3D Printing’s Impact on Key Industries

The 3D Printing Trend Report sheds light on the primary applications of 3D printing, with prototyping leading the way at 66 percent. It is closely followed by tooling and the production of end-use parts, which allows for mass customization and minimizes machine downtimes.

The aerospace industry, having been an early adopter of additive manufacturing, continues to play a pivotal role in the 3D printing landscape. The technology’s capacity to fabricate lightweight components that enhance aircraft fuel efficiency remains a compelling feature for this sector.

Furthermore, additive manufacturing offers a high degree of flexibility to the medical industry. Currently, it is employed in the manufacturing of patient-specific implants, prosthetics, surgical guides and instruments, anatomical models, dental products, and a range of other applications.

The report also delves into other industries that are poised for transformation, including food, fashion, motorsports, bioprinting, and space exploration.

The Future of 3D Printing

Looking ahead, the report delves into the profound impact of AI and smart materials, including 4D printing, on the landscape of additive manufacturing.

It provides valuable insights from industry experts regarding how cutting-edge technologies such as AI and smart materials, particularly 4D printing, are poised to shape the future of additive manufacturing. AI-driven solutions, like in-print monitoring, have the potential to make significant improvements in terms of consistency and quality control within the 3D printing process.

Furthermore, AI tools hold the promise of streamlining generative design processes, making complex design elements more accessible in the realm of 3D printing.

Smart materials, a key frontier in this field, have the potential to be a game-changer in healthcare, particularly for applications like targeted drug delivery. Beyond healthcare, numerous other industries, including aerospace, furniture, packaging, and wearables, are actively exploring the potential of smart materials to create innovative and transformative solutions.

Textile printing.

Textile printing.

Green by Design: Additive Manufacturing and Sustainability

The 3D Printing Trend Report underlines how 3D printing represents a manufacturing option with a significantly reduced environmental footprint.

To begin, it generates substantially less waste when compared to traditional manufacturing methods. Additive manufacturing also facilitates local production, thereby eliminating the environmental impact associated with long-distance transportation.

Moreover, with the increasing availability of filaments made from recycled sources, the utilization of recycled materials in 3D printing is on the ascent.

Looking to the Future

At present, a notable 20.72 percent of the survey participants included in Hubs’ research utilize 3D printing for the production of end-use parts. However, as the technology continues to advance, offering enhanced efficiency, speed, and accessibility, Hubs anticipates a consistent growth in the adoption of 3D printing as a fully-fledged manufacturing method.

The narrative of 3D printing is marked by continuous evolution. Moving forward, we can anticipate new dimensions of this versatile technology that will reshape our world and the way we engage with it.