Freshen your ADA-compliant signage during the planning stages. Photo: Clarke Systems.

When embarking on an interior ADA project, whether working directly with a manufacturer or taking on production work independently, careful planning is crucial. Beyond understanding ADA guidelines, there are several key considerations during the early planning stages that sign shops must pay attention to:

1. Regulations: Local vs. Federal

While the Federal ADA code serves as the basis for all regulations, local interpretations may be more stringent. Sign makers must prioritize adherence to local ADA interpretations. Charles Kelly, Jr., President of architectural sign systems provider Clarke Systems, emphasizes the importance of confirming local region codes before proceeding.

2. Site Survey: Assumptions

When dealing with existing signage during ADA projects, such as renovations or incorporating ADA elements with pre-existing signs, assumptions can lead to non-compliance. Kelly advises surveying the site thoroughly, identifying irregularities, and addressing any wall obstructions or door swing considerations before installation.

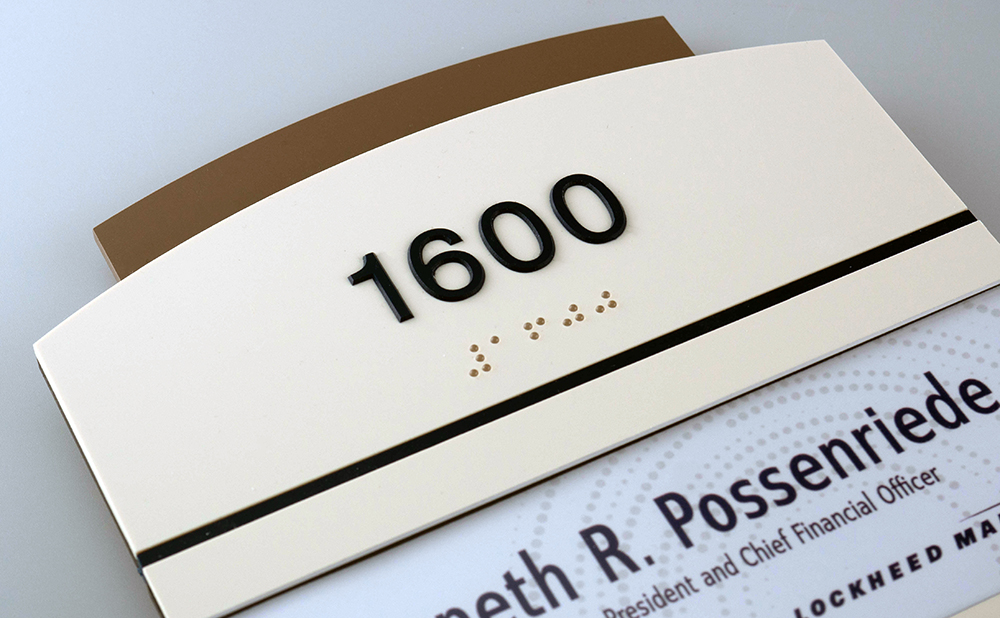

3. Deliverables: Numbers vs. Text

Choosing between numeric or text-based signage impacts ongoing office changes and budget considerations. Kelly recommends using numbers with changeable inserts for rooms experiencing frequent changes, facilitating compliance with ADA while keeping information up-to-date.

4. Design: Font Decisions

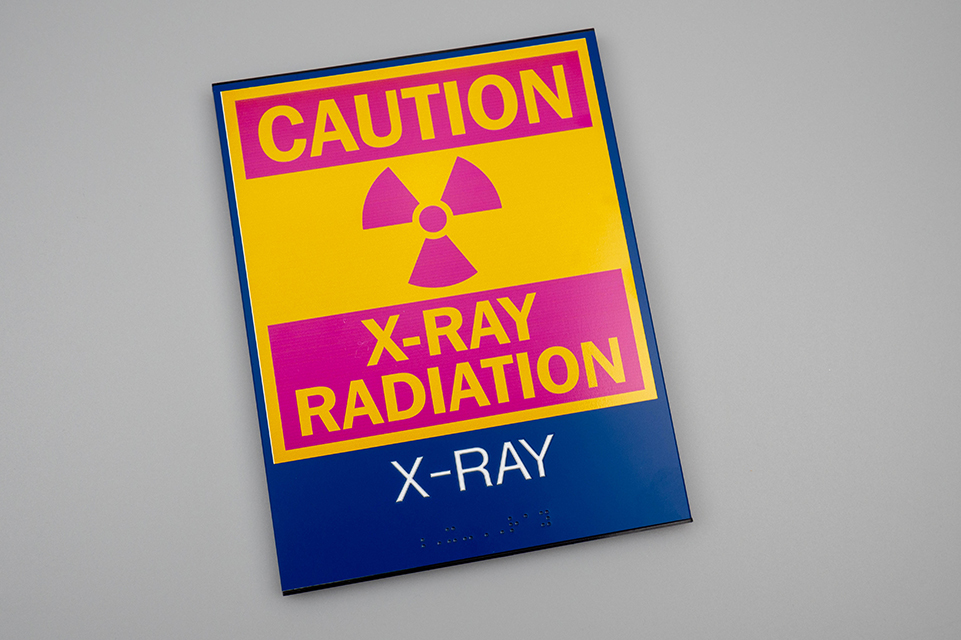

Selecting ADA-compliant fonts is critical for legibility. Arial, Helvetica, Times New Roman, and Verdana are recommended choices. Additionally, meeting the 4.5-to-1 contrast ratio can be challenging, but manufacturers like Rowmark offer color palettes to simplify the process.

5. Samples: Check with Manufacturers

Manufacturers often provide standard samples for customer evaluation. For large ADA signage orders, obtaining a working sample before full production ensures the final product aligns with expectations, especially concerning color backgrounds, text, and imagery.

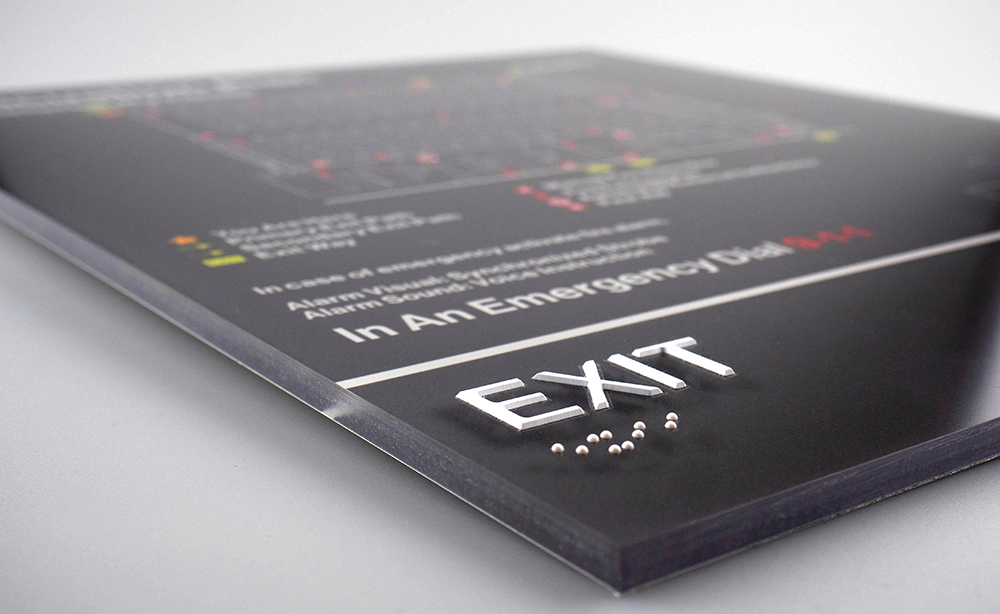

6. Trends: 3-D Direct Printing

Embracing trends like 3-D direct printing can be a time-saving breakthrough. High-speed printers producing multiple layers of ink result in a 1/32-inch-high graphic. This method, unlike traditional ones, allows for a finished sign ready for installation immediately, provided ADA guidelines are adhered to.

Kelly emphasizes the complementary role of other equipment, such as rotary engravers and laser engravers, in conjunction with 3-D direct printing. These technologies not only enhance ADA project capabilities but also expand a shop’s overall production capabilities.

In conclusion, a comprehensive approach to planning, considering local regulations, conducting thorough site surveys, choosing appropriate deliverables, making informed design decisions, checking with manufacturers, and embracing innovative trends ensures a successful and compliant interior ADA project for sign shops.

ADA-compliant sign. Photo: Clarke Systems.

ADA-compliant sign. Photo: Clarke Systems.

Up-close view of Braille placement on an ADA-compliant sign. Photo: Clarke Systems.

Up-close view of Braille placement on an ADA-compliant sign. Photo: Clarke Systems.

Review all the mounting areas and pay attention to any wall obstructions. Photo: Clarke Systems.

Review all the mounting areas and pay attention to any wall obstructions. Photo: Clarke Systems.

The need for a 4.5-to-1 contrast ratio can be challenging. Photo: Clarke Systems.

The need for a 4.5-to-1 contrast ratio can be challenging. Photo: Clarke Systems.