Mimaki USA, a leading manufacturer of wide-format inkjet printers and cutters, has introduced two groundbreaking sustainable technologies in textile printing at ITMA 2023, held in Milan, Italy. These innovations, the environmentally friendly Textile Pigment Transfer Printing System and the Neo-Chromato Process, are being showcased for the first time, setting Mimaki apart as a leader in sustainable and eco-friendly solutions for the textile printing industry.

Introducing a Revolutionary Approach to Printing: Textile Pigment Transfer Printing System

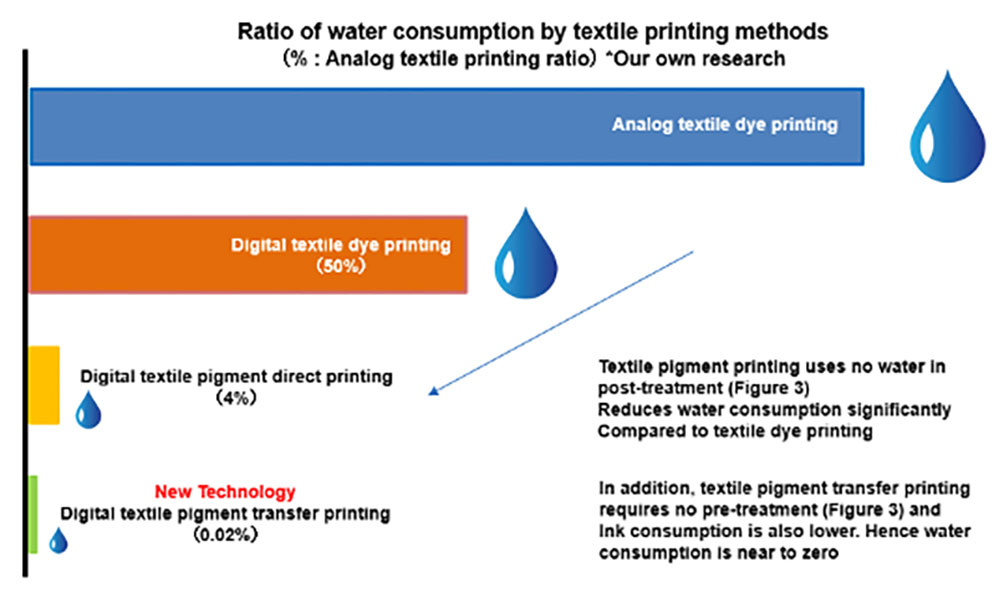

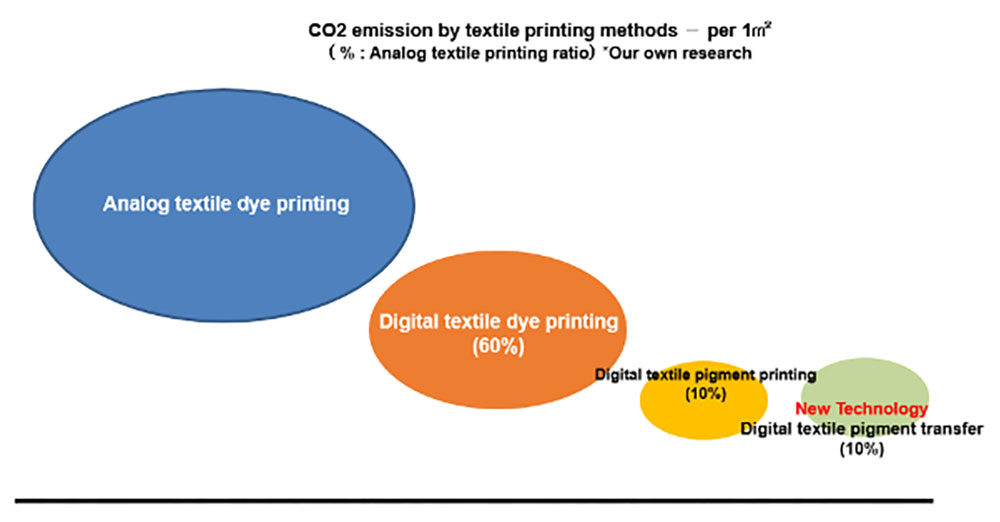

In response to growing demand for more sustainable and environmentally friendly printing methods, Mimaki has spearheaded the development of a Textile Pigment Transfer Printing System. Traditional dyeing methods for natural fibers using dyes and pigments generate nearly 2 billion tons of wastewater, contributing to almost 20 percent of all industrial wastewater. This wastewater is laden with chemical byproducts stemming from pre and post-dyeing processes across the globe. Beyond the environmental ramifications, large-scale dyeing facilities also significantly contribute to CO2 emissions due to both their production processes and the often necessary overseas transportation.

Mimaki’s Textile Pigment Transfer Printing System promises a more sustainable and eco-friendly alternative to these traditional methods. By reducing the reliance on water-intensive dyeing processes, it not only minimizes the environmental impact but also lessens the carbon footprint associated with dyeing facilities. This breakthrough technology signifies a major stride toward greener and more responsible textile printing, addressing both water conservation and carbon emissions concerns.

Figure 1.

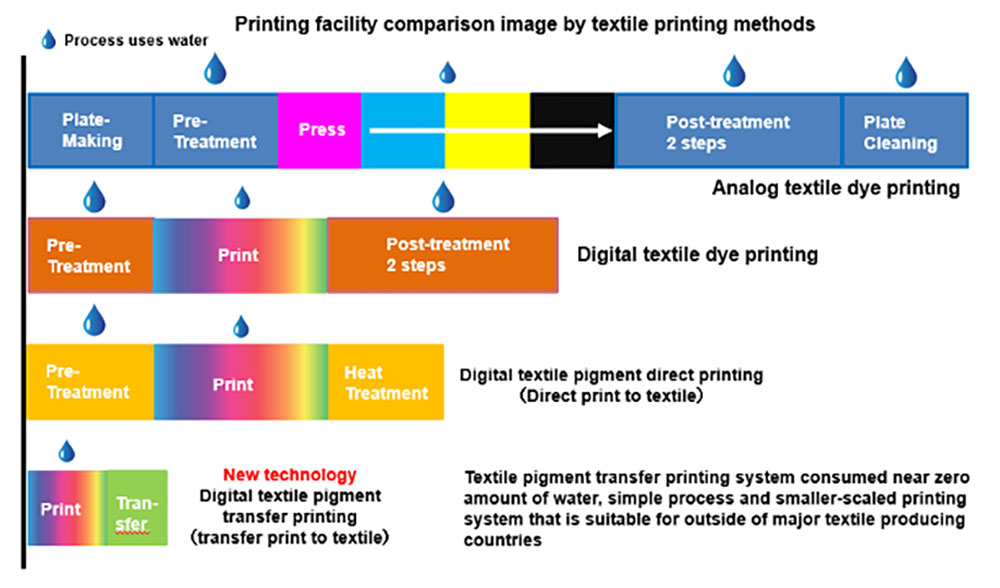

Mimaki’s Textile Pigment Transfer Printing System is an innovation that relies on minimal water usage for printing, effectively reducing the carbon footprint. This is made possible through its on-site capabilities and compact-scale structure, as illustrated in Figures 1 and 2.

Figure 2.

Figure 2.

The compact design of this system also offers a cost-effective advantage when compared to traditional textile dye printing methods, as demonstrated in Figure 3. Its affordability makes it a viable option for small-scale textile production, even outside the major textile-producing countries. As a result, this not only lowers the environmental impact but also mitigates CO2 emissions associated with international transportation of textile goods.

Figure 3.

Figure 3.

The Textile Pigment Transfer Printing System is composed of three integral components: Textile Pigment Ink, Textile Transfer Paper, and the Transfer System. Notably, the textile pigment ink is presently in the process of obtaining bluesign® certification, and we anticipate receiving the official approval in September 2023. This certification serves as a testament to the system’s commitment to sustainability and adherence to stringent environmental and safety standards in textile production.

Reducing Waste with Reused Textiles

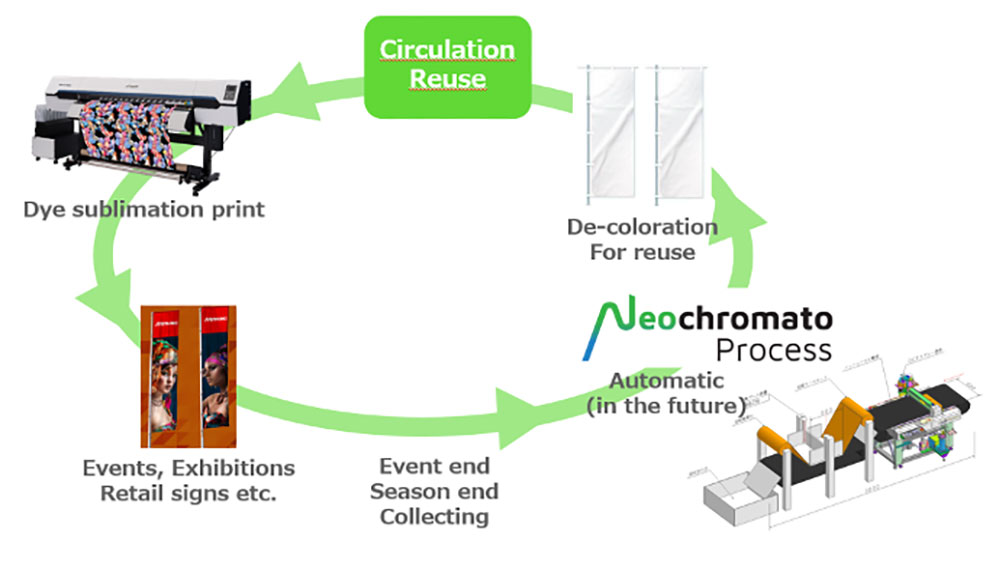

Another noteworthy introduction at ITMA 2023 is Mimaki’s groundbreaking Neo-Chromato Process, which represents a paradigm shift in the reuse of colored polyester textiles.

The Neo-Chromato Process redefines the possibilities of recycling polyester textiles that have previously undergone dye sublimation technologies. This innovative procedure involves the removal of color from these textiles, rendering them ready for immediate re-printing or dyeing. This significant advancement not only promotes environmental responsibility but also substantially reduces the carbon footprint associated with textile recycling. Furthermore, the Neo-Chromato Process offers a sustainable approach without limitations on the number of times polyester materials can be treated. This approach not only conserves water but also minimizes pollution, emphasizing its eco-friendly attributes.

Figure 4.

Figure 4.

Colored polyester textiles are typically employed for short-term applications such as banners, backlit signs, tablecloths, fast fashion apparel, and sportswear. Regrettably, these materials often face disposal through incineration, with only a fraction being recycled.

Mimaki’s research indicates that polyester textiles constitute a substantial portion, approximately 60 percent, of the 92 million tons of discarded textiles globally. This waste has far-reaching environmental consequences.

The Neo-Chromato Process emerges as a transformative solution, effectively obviating the need for incineration or traditional recycling methods. By reintegrating these polyester textiles into new uses, this innovative approach is fundamentally sustainable, offering a much-needed reprieve for the textile industry and the environment.

These two remarkable announcements reflect Mimaki’s unwavering commitment to introducing innovations to the printing market that prioritize sustainability and the reduction of environmental impact. Listening keenly to the needs of customers worldwide, Mimaki USA considers it a moral duty to actively collaborate with industry trends and explore the full potential of these transformative technologies.