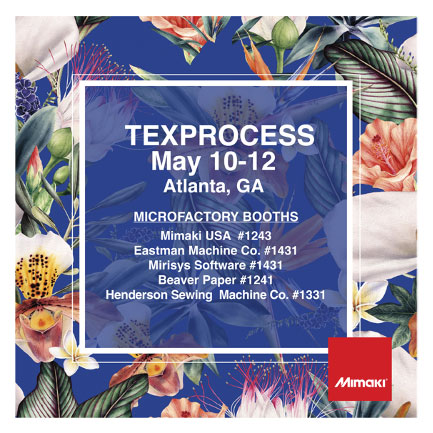

Mimaki USA, a prominent manufacturer of wide-format inkjet printers and cutters, has exciting plans to participate in a textile microfactory at Texprocess Americas 2023. Mimaki’s textile specialists from their Atlanta and Los Angeles offices will be available at booth #1243, showcasing their innovative TS100 and TS330 series of dye sublimation printers.

This on-site microfactory, a collaborative effort between Mimaki, Beaver Paper, Eastman Machine Co., Henderson Sewing Machine Co., PremEx Solutions, and Mirisys Software, will bring the concept of on-demand textile printing to life. Visitors will be guided through the entire process of creating a tote bag, from the initial design concept to the finished product.

In the past, textile printing production relied on sales forecasts, resulting in a slow response to rapidly changing market trends and an abundance of unsold inventory. This traditional approach imposed a heavy environmental burden, led to high production costs, and resulted in low profitability.

The microfactory concept offers a cost-effective alternative that allows companies to produce textiles in any volume, minimizing the need for excess stock and associated risks, ultimately increasing profitability. Digital textile printing, a key component of this new model, enables customizable, demand-driven production, providing limitless design variations and the agility to swiftly respond to market trends. This approach empowers companies to deliver the right products in the right quantities at the right time.

What sets a microfactory apart is its emphasis on sustainability and efficiency:

- Energy, Materials, and Time Savings: Microfactories are designed to minimize energy consumption, reduce material waste, and streamline production processes, resulting in time savings.

- Reduced Real Estate and Storage Requirements: Microfactories occupy less physical space and require less storage, which is cost-effective and environmentally friendly.

- Small Ecological Footprint: Microfactories are eco-conscious, striving to minimize their environmental impact.

- Waterless Printing: Some microfactories, like those specializing in transfer and textile pigment printing, use no water during the process and promote the use of eco-friendly fabrics.

- Scalability: Microfactories are highly scalable, allowing them to quickly adapt to changing production needs as sales volumes increase.

- Advanced Digital Techniques: Microfactories leverage the latest digital technologies, offering endless creative possibilities, allowing for the rapid transformation of the latest designs into production, reducing time to market.

This innovative microfactory model not only transforms the textile industry but also aligns with modern, sustainable, and flexible production practices that benefit both businesses and the environment.