The new attention-grabbing sign at Grand Champion Meats features a giant EPS bratwurst atop it.

Traffic passing by Grand Champion Meats is now treated to a captivating sight—a colossal bratwurst perched atop grilling fork prongs, accompanied by an illuminated sign cabinet and an electronic message center (EMC).

Nestled in Foley, Minnesota, Grand Champion Meats boasts a proud legacy as an award-winning meat market and butcher shop spanning five decades. Despite already having a single-pole-mounted LED-illuminated sign cabinet coupled with a Watchfire EMC attached to a sturdy six-inch-round steel pipe, the owner desired to elevate their signage to new heights.

In pursuit of a more alluring and memorable display, the owner enlisted the expertise of Indigo Signs, a comprehensive full-service sign company headquartered in Fargo, North Dakota, with an additional six locations scattered across Minnesota and North Dakota. According to Bob Wolfe, an account executive at Indigo Signs, the owner’s vision was clear—he sought a sign that would not only catch the eye but also leave an indelible mark on the minds of passersby, prompting them to halt and capture the moment with photographs.

The previous Grand Champion Meats sign.

The previous Grand Champion Meats sign.

The initial concepts for the signage were originally drafted in 2020 by Indigo Signs before Wolfe’s involvement, but they faced practical challenges due to wind load issues associated with the existing steel pole and attached cabinets. Alternative designs were explored, featuring elements separate from the sign itself and installed adjacent to it.

When Wolfe and his team took charge of the project, their primary objective was to adapt the customer-provided design to be structurally viable. After a meticulous evaluation, they concluded that a new foundation for the pole was essential. Simultaneously, they worked towards enhancing the overall visual allure of the signage.

Recognizing the prominence of Grand Champion Meats’ bratwurst product, Indigo Signs aimed to seamlessly integrate this theme into the revamped design. Their innovative solution involved concealing the exposed steel pole with a grilling fork handle, creating the illusion of two grilling fork prongs piercing through the double-sided EMC and illuminated sign cabinet. Central to the design was a striking 49-inch-tall-by-143.75-inch-wide bratwurst, skillfully skewered by the two grilling fork prongs, ensuring a visually captivating and cohesive representation of the brand’s core offering.

Initial sign renderings were deemed mechanically unusable because of wind load concerns.

Initial sign renderings were deemed mechanically unusable because of wind load concerns.

The novel wind-load engineering solution prompted a redesign of the sign, transitioning from a single pole at the base to two poles towards the apex. While the existing EMC could be retained, the plate-mounted structure required recreation to enhance structural integrity and accommodate the twelve-foot-long bratwurst.

Indigo Signs ingeniously addressed this challenge by incorporating a ten-by-ten-inch steel spreader bar within the illuminated cabinet. This bar served as the foundation for two four-by-four-inch steel tube poles, effectively emulating the appearance of grilling fork prongs. This mouth-watering redesign garnered not only excitement from Grand Champion Meats but also enthusiasm from the team at Indigo Signs, eager to commence work on bringing the vision to life.

With responsibility for reconstructing the illuminated sign cabinet and crafting the new sign poles falling on Indigo Signs, they enlisted the expertise of Signs By Benchmark, a renowned interior and exterior foam-core manufacturer. Based in Watertown, South Dakota, the company eagerly took on the task of sculpting the oversized bratwurst and grilling fork handle out of expanded polystyrene (EPS), adding a layer of artistry to the structural enhancements.

Initial sign renderings were deemed mechanically unusable because of wind load concerns.

Initial sign renderings were deemed mechanically unusable because of wind load concerns.

“We’ve built a strong relationship with Indigo Signs through our collaboration on numerous projects over the years,” says Jamie Kakacek, senior designer at Signs By Benchmark. “This familiarity allowed us to navigate the challenges seamlessly. Each project brings its own set of unique obstacles, and the lessons learned from these experiences contribute to our continuous improvement.”

For the new sign components, Signs By Benchmark opted for aged one-pound-density EPS. Kakacek explains, “Given that our product didn’t bear any load, our nominal density appeared to be sufficient for this application.”

The process involved hot wire-cutting the EPS into the initial shape of the bratwurst, followed by meticulous sculpting to achieve a rounded appearance. Kakacek adds, “Since cooked brats aren’t perfectly smooth, we didn’t need to obsess over achieving a flawless round shape. In fact, some irregularity worked to our advantage, contributing to the authentic aesthetic of the final product.”

The company hot-wire cut the EPS into the general shape of the bratwurst.

The company hot-wire cut the EPS into the general shape of the bratwurst.

In the initial design phase, Signs By Benchmark collaborated closely with Indigo Signs to construct a central frame for the bratwurst. Jamie Kakacek elaborates, “This not only enhanced the structural integrity of our product but also provided a means for them to securely attach it to the cabinet frame.”

To create the bottom handle section, various pieces were precision-cut and then assembled to snugly fit around the central mounting pole. Kakacek adds, “After assembly, we incorporated a radius cut on the corners to impart a softened aesthetic to the handle, enhancing the overall visual appeal.”

Signs By Benchmark used a water-based paint system to give a detailed, realistic appearance.

Signs By Benchmark used a water-based paint system to give a detailed, realistic appearance.

When the customer initially inquired about a color match for the grilled brat, Bob Wolfe of Indigo Signs entertained the idea of personally grilling brats for color reference. However, he ultimately decided to grant Signs By Benchmark the creative freedom to take the lead. Wolfe recalls, “I thought it would be better to give Signs By Benchmark a creative license to just run with it. They have a unique approach with hazing, airbrushing, and texturing that adds a special touch. It was truly fascinating to witness their process, especially when they meticulously added textured grill marks to the EPS bratwurst and further enhanced the finished product through painting.”

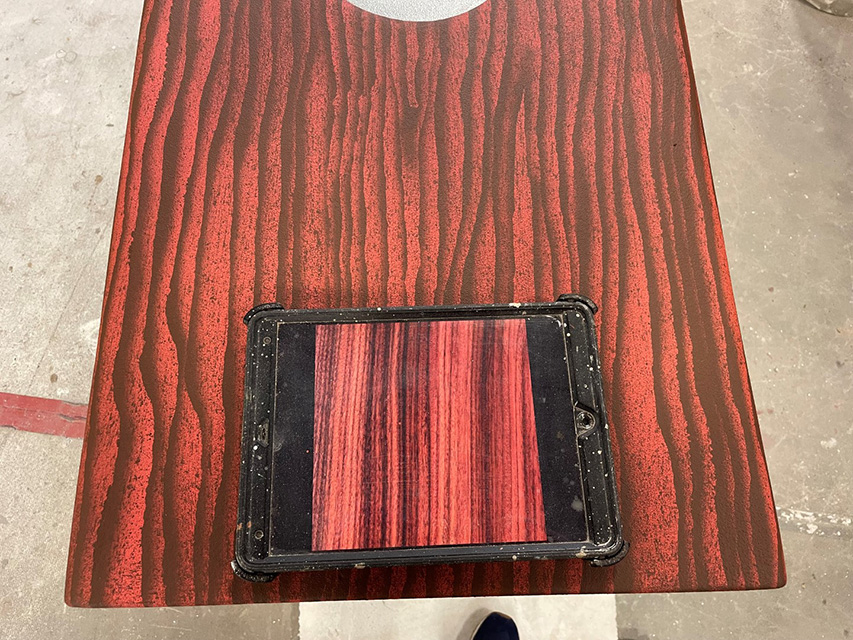

For the detailed and realistic appearance of all the components, Signs By Benchmark employed a water-based paint system. Notably, they achieved the wood grain on the fork handle by free-handing it, using a tablet loaded with images sourced from Google as a reference—a testament to their skilled craftsmanship and attention to detail.

Signs By Benchmark used their tablet to freehand the wood grain the fork handle portion.

Signs By Benchmark used their tablet to freehand the wood grain the fork handle portion.

“The key was achieving a seamless blend between the wood grain and the colors of the bratwurst, and our extensive experience with water-based paints proved invaluable in achieving that,” notes Kakacek. “After the painting process, we applied a high-gloss clear coat to add a subtle sheen, giving the parts the appearance of fresh meat right off the grill.”

Providing details on the weight of the components, Kakacek mentions that the grilling fork handle weighs approximately 75 to 100 pounds, while the bratwurst, excluding the interior frame, comes in at around 150 pounds. To ensure safe transport, Signs By Benchmark securely mounted the finished pieces inside a crate, shipping the entire assembly back to Indigo Signs.

The finished fork handle.

The finished fork handle.

The installation process proceeded seamlessly, wrapping up in less than a day. The eight-by-eight-inch single pole had already been securely encased in a concrete caisson, extending 108 inches below the ground.

The grilling fork handle, expanding the pole’s appearance to twenty inches in width, was designed with a central sleeve facilitating easy sliding onto the main mounting pole. Kakacek explains, “We incorporated metal into the top of the handle to ensure secure attachment to the frame on-site, minimizing any potential movement.”

Indigo Signs’ installation team utilized crane and basket trucks to maneuver the grilling fork handle onto the pole first, followed by the placement of the electronic message center. Wolfe details the process, “The EMC was pre-mounted to the framework, allowing us to smoothly slide it over the top of the pole. The final step involved meticulous leveling to ensure it perfectly aligned with the grade.”

Setting up the trucks and cranes for installation.

Setting up the trucks and cranes for installation.

The illuminated cabinet was then slid over the pole and attached to the ten-by-ten-inch steel tube spreader bar that eased the transition from a single pole to a double pole. “The cabinets mounted well to it,” remarks Wolfe.

The bratwurst frame was built with a match plate system that bolts to the top of the cabinet. “We then built the top points of the tongs out of foam so they could bolt into the pick point locations and complete the look,” says Kakacek.

Indigo Signs fabricated a threaded bolt that was welded into the top tabs of the two prongs to hold the Benchmark brat.

Lifting the giant bratwurst into place.

Lifting the giant bratwurst into place.

“Upon setting the actual bratwurst on the two poles, we secured the two fork points by essentially screwing them into the top of the brat,” Wolfe details. “Given that the top of the brat has a somewhat curved surface with a couple of flat areas, our installers aligned the two prongs and started spinning them. It was a smooth process, and in no time, the installation was successfully completed!”

The new sign has brought extra attention and photo opportunities to Grand Champion Meats.

The new sign has brought extra attention and photo opportunities to Grand Champion Meats.